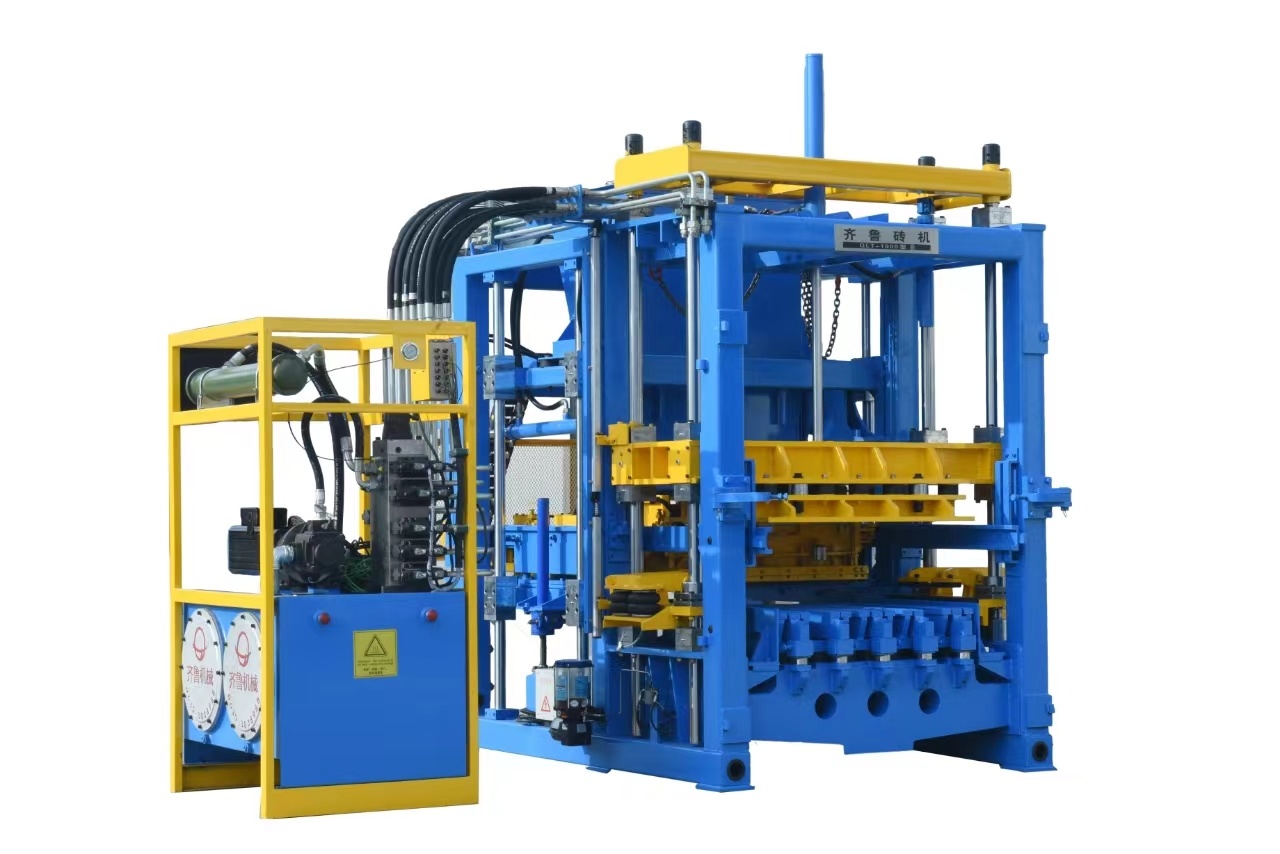

Full-automatic QT10-15C-free brick machine (with fabric machine)

Classification:

Key words:

QT10-15C-free

Product Description

QT10-15C type automatic non-burning brick machine technical parameters (with fabric machine)

|

QT10-15C type technical parameters |

|||

|

Maximum molding area |

1100 × 850mm |

vibration table |

2 × 11KW |

|

Height of finished product |

50-300mm |

vibration frequency |

47-75HZ |

|

electronic control system |

SIEMENS |

||

|

Forming cycle |

10-20 seconds (depending on the shape of the product) |

Total installed capacity |

42.25KW |

|

Exciting force |

80KN |

Total |

12 tons |

|

Pallet Size |

1400 × 900 ×(12-45)mm |

||

|

Number of molding blocks |

390 × 190 × 190mm(10 pieces/mold) |

||

(with fabric) QT10-15C type automatic non-burning brick machine main technical features:

1. molding host: using German technology design, including 4 patented technologies (host system patent, hydraulic system patent, laminated plate system patent, vibration system patent), stable performance, high product density, size standard, high output, beautiful and reasonable appearance design.

2. vibration system: 1. The patented vibration technology of Qilu brick machine is adopted. The integrated design of vibrator and vibration platform, the combination of dynamic and static platforms, penetrating vibration, high vibration frequency, variable frequency vibration of the power part of the vibrator, the anti-reverse wire pad imported from Sweden, the bolt adopts Taiwan Jinyi high-strength bolt, and the link between each part is more stable. 2. Siemens variable frequency vibration motor is directly connected with connecting rod type soft connection transmission assembly, which saves belt transmission link in traditional vibration mode, has fast vibration speed and large vibration force, and the molding speed cycle of each plate brick is increased by 3-4 seconds, and the output is increased by 20%.

3. hydraulic system: The patented appearance design of Qilu brick machine is adopted, the appearance is exquisite, the trapezoidal design of the oil pipes is neatly arranged, and the direction of the oil pipes is more reasonable. The main motor adopts Siemens motor, the main oil pump, double proportional valve and solenoid valve all adopt Japanese oil research, and the core technology of Qilu brick machine is assembled, with stable performance, extremely low failure rate, mature design, reasonable structure, fast and stable walking speed of each movement. The tubing is imported from Italy, with aging resistance, no oil leakage and long service life. The joint wire adopts the products of domestic high-end manufacturers to avoid oil leakage and oil leakage, ensure stable pressure and good operation of equipment.

4. electric control system: Qilu brick machine computer PLC automatic control integrated technology, the whole line of each part of the independent frequency conversion design. PLC adopts Taiwan Fengwei, touch screen, sensor, frequency converter and circuit accessories all adopt famous brand accessories such as Omron, Taiwan Shilin, Jie Tong, Sine, ABB, etc.

5. cloth machine system: the cloth car uses 360 ° to rotate in the same direction to force the cloth to stir twice, so that the cloth is the most uniform, the cloth speed is fast, the product density is highly consistent. The bottom plate of the cloth car adopts Shanghai Baosteel NM400 high-strength wear-resistant plate, which greatly improves the service life. The cloth shaft adopts 20 chromium quenching, which has good willfulness and is not easy to break. The stirring tooth adopts 20 chromium quenching, which has good willfulness and wear resistance. The bolt type design is more convenient to replace. The electric control type door is adopted. The discharging amount can be adjusted at will according to the amount of different brick types, and the blanking is more accurate.

6. balance system: gantry type and balance bar double balance are adopted, the upper and lower molds are accurately injected into the mold, the phenomenon of mold clamping is avoided, and the service life of the mold is prolonged. The upper and lower molds are designed as double boxes. The middle shock-absorbing rubber pad protects the pressure head oil cylinder, and the four-point limit ensures the level of lower pressure of the upper mold and protects the rubber pad at the same time.

7. brick receiving machine: the operation is frequency conversion control, the speed is adjustable, and the operation is relatively stable.

8. belt conveyor: the old traditional system is eliminated, and the latest feeder system is adopted. The finished materials are mixed twice to make the materials evenly put into the storage hopper.

9. cloth truck lifting platform: the use of lift lifting, beautiful, practical, easy to change the mold.

10. safety net: push-pull more convenient, easy to use, more secure.

Key words:

Burning-free brick machine

recommend products

Welcome your message consultation

TEL:+86-400-006-3568

TEL:+86-400-006-3568 E-mail:qlmszj1@163.com

E-mail:qlmszj1@163.com