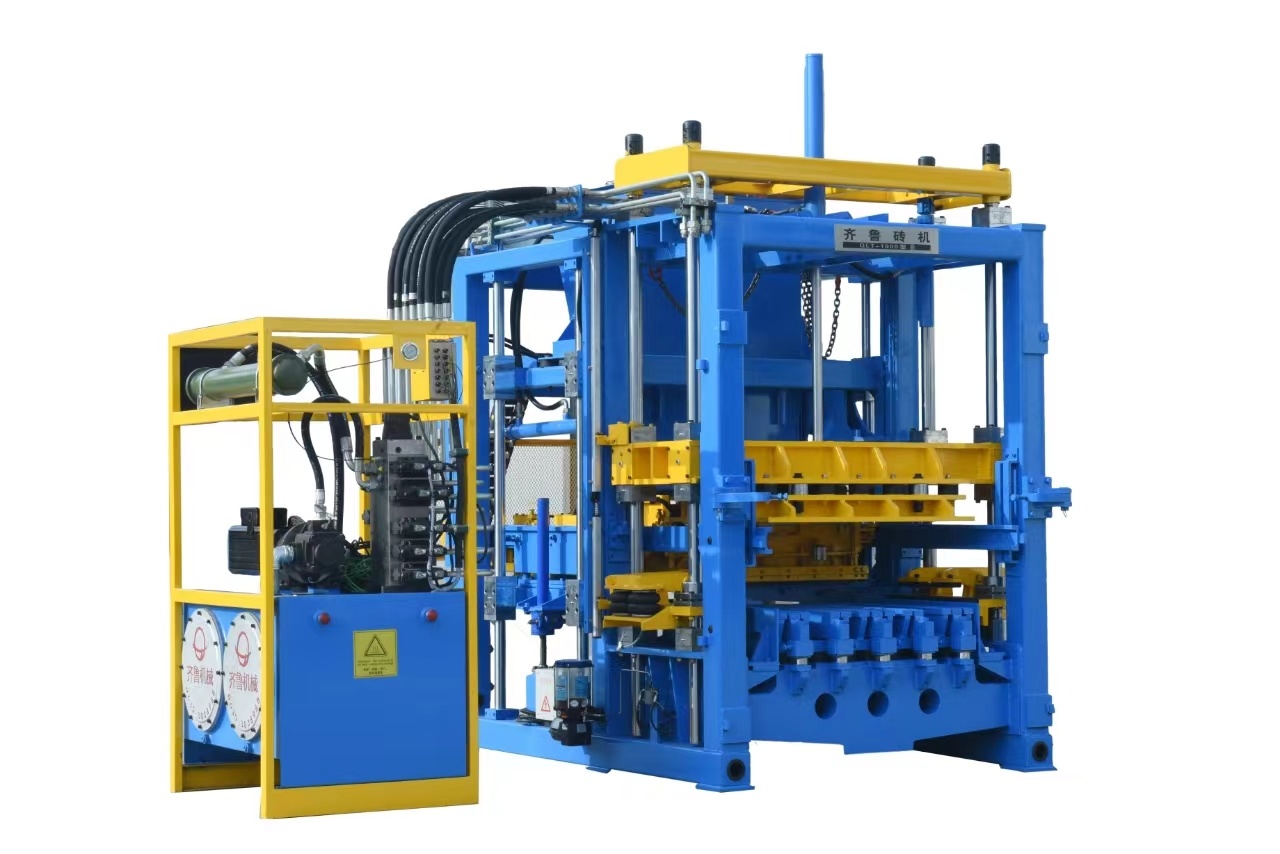

Full-automatic QT10-15-free brick machine production line (with fabric machine)

Classification:

Key words:

QT10-15-free

Product Description

Main technical features:

1. It is suitable for large and medium-sized enterprises to invest in the establishment of automatic block equipment production line to realize automatic production.

2. The automatic block production line is an automatic production line with frame maintenance, with mature technology, simple configuration and compact operation mode, which can realize automatic continuous production from feeding to block forming and palletizing.

3. Mature vibration technology respectively cloth and vibration molding, making cloth homogenization, molding optimization.

4. With the addition of a fabric machine, users can produce tiles of different colors according to their own requirements.

Main technical parameters:

|

Parameter Name |

Parameter Value |

|

|

Maximum machine size |

Long 6800mm * wide 2090mm * high 3125mm |

|

|

Rated pressure of hydraulic system |

21MPA |

|

|

Main vibration form |

Table vibration |

|

|

vibration frequency |

47-75HZ |

|

|

vibration acceleration |

10-15g |

|

|

Adapt to brick height |

50-200mm |

|

|

Size of pallet |

Wooden |

1100*870*(40±1)mm |

|

Iron |

1100*870*(8~10±1)mm |

|

|

made of bamboo |

1100*870*(20~25)mm |

|

|

Forming cycle |

12-25 seconds, need to add fabric 20-25 seconds |

|

|

hourly output |

Road brick (200*100*60mm) |

160m3 |

|

Standard brick block (390*190*190mm) |

25m3 |

|

|

Feeding device capacity |

Effective volume of hopper 0.7m3 |

|

|

Feeding trolley effective volume 0.2m3 |

||

|

Overall power |

Host 47.68KW |

|

|

Weight of whole machine |

9840kg |

|

Main product specifications and output per board:

|

Standard brick |

240x115x53mm |

48 blocks/board |

|

porous brick |

240x115x90mm |

24 blocks/board |

|

pavement brick |

200*100*60mm |

27Block/board |

|

Curb |

1000x300x120mm |

2 pieces/board |

|

heterosexual chain brick |

24 blocks/board |

|

Key words:

Burning-free brick machine

Previous Page

recommend products

Welcome your message consultation

TEL:+86-400-006-3568

TEL:+86-400-006-3568 E-mail:qlmszj1@163.com

E-mail:qlmszj1@163.com