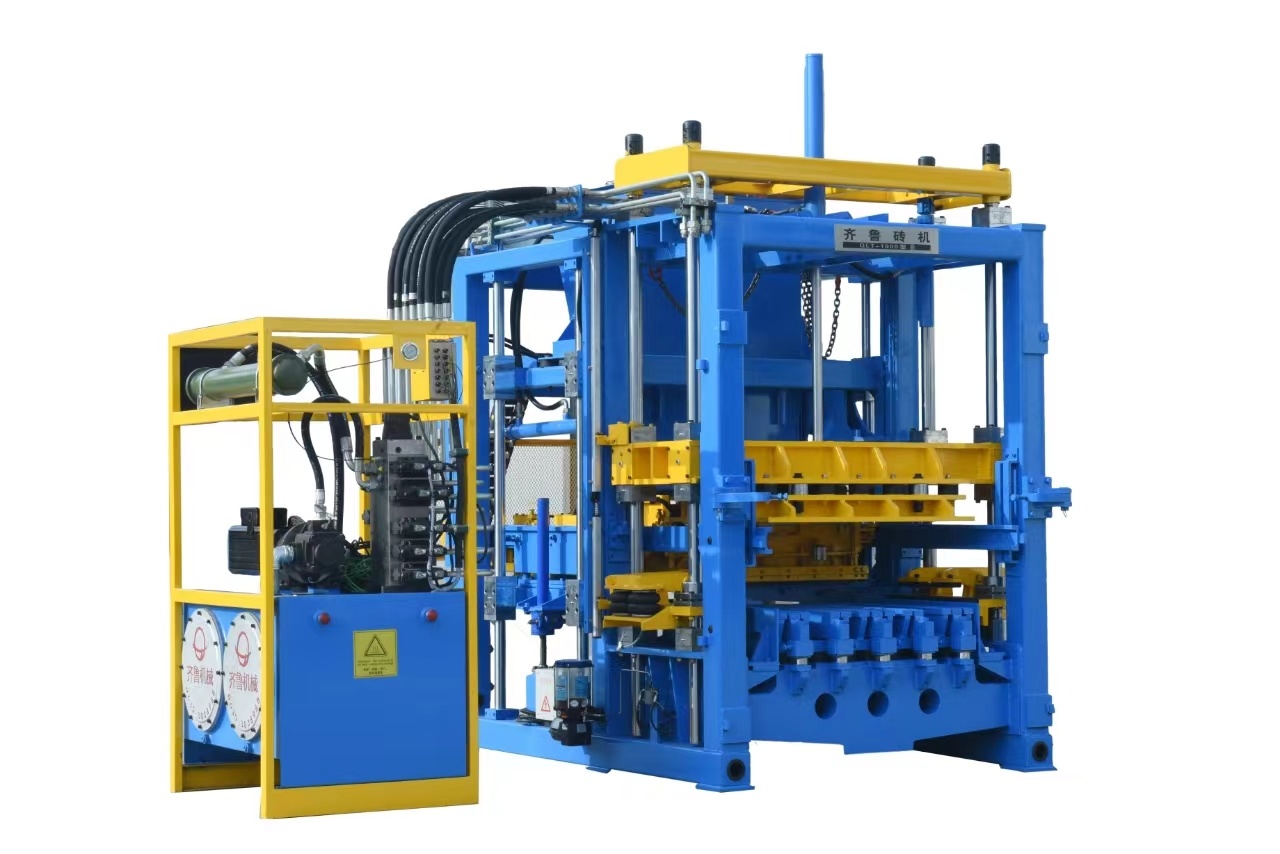

New QTA10 fully automatic brick making machine

Classification:

Key words:

New QTA10 fully automatic brick making machine

Product Description

Detailed Introduction of QTA10 Equipment

(I) Technical Parameters of QTA10

Main Technical Parameters

QTA10 Technical Parameters | |||

Maximum Forming Area | 1,100×900mm | Main Vibration Type | Table Vibration |

Main Unit External Dimensions | Length 5700 × Width 2700 × Height 3000 | ||

Finished Product Height | 50-300mm | Vibration Frequency | 45-75HZ |

Electrical Control System | VlGOR | ||

Forming Cycle | 12-18 seconds (depending on product shape) | Total Power | 67.8KW |

Exciting Force | 120KN | Total Weight | 14.5T |

Stacker Size | 1,150×950×(12-35)mm | ||

Number of Forming Blocks | 390×190×190mm (10 blocks/mold) | ||

Main Components and Advantages of QTA10 Fully Automatic Equipment

Forming Host: This equipment is a vibration-pressure type four-column brick forming machine. Due to its unique design and advanced forming principle, it realizes automatic feeding, brick output, aggregate feeding, and vibration stacking frequency conversion. It has the characteristics of multiple uses, stable performance, easy operation, and high output.

1. Vibration System: Using four-axis vibration, Qilu brick machine patented technology (vibrator and vibration platform integrated design patent number:ZL 2020 30277959.6) penetration-type vibration, high vibration frequency, uniform vibration force, and the power part of the vibrator is frequency conversion vibration. Maximizing the use of effective vibration force, evenly transmitting the vibration force to each part of the mold box, maximizing the improvement of product density and mold service life.

2. Hydraulic System: Independently designed by Qilu Brick Machine, the oil pipe design is arranged neatly, and the oil pipe path is more reasonable. The main oil pump, double proportional valve, and electromagnetic valve all use high-end domestic manufacturer components, assembled with Qilu brick machine core technology, stable performance, extremely low failure rate, fast and stable running speed of each action. The oil pipe uses imported Italian oil pipes, which are resistant to aging, leak-proof, and have a long service life. The threaded joints use products from high-end domestic manufacturers to avoid oil leakage and seepage, ensuring stable pressure and good equipment operation.

3. Electrical Control System: Qilu Brick Machine PLC automatic (three frequency conversion) integrated control technology, independent frequency conversion design for each part of the entire line. The PLC uses Taiwan Fengwei, touch screen, sensors, frequency converters, and circuit accessories all use famous brand accessories such as Omron, Taiwan Shilin, Jeton, Zhengxian, and ABB.

4. Material Distribution System: New semi-enclosed hopper, the hopper adopts electrically controlled opening, the feeding amount can be adjusted at will according to the material consumption of different brick types, the feeding is more precise, and the feeding trolley adopts a reciprocating tooth-type design, quickly and evenly adding materials to the mold. The bottom plate of the feeding trolley uses Shanghai Baogang NM400 high-strength wear-resistant plate, greatly improving the service life, and the stirring teeth use 35cro quenching, good toughness, good wear resistance, and bolt-type design for easier replacement.

5. Brick Picking Machine: The operation is frequency conversion controlled, the speed can be adjusted, the operation is stable, and the finished products are undamaged.

6. Feeding Trolley Lifting Platform: Using hydraulic lifting, beautiful, practical, and convenient for mold replacement.

7. Safety Net: Using a hanging safety net, maintenance and disassembly are more convenient and easier to use, and safer.

Key words:

Product classification

Burning-free brick machine

recommend products

Welcome your message consultation

TEL:+86-400-006-3568

TEL:+86-400-006-3568 E-mail:qlmszj1@163.com

E-mail:qlmszj1@163.com