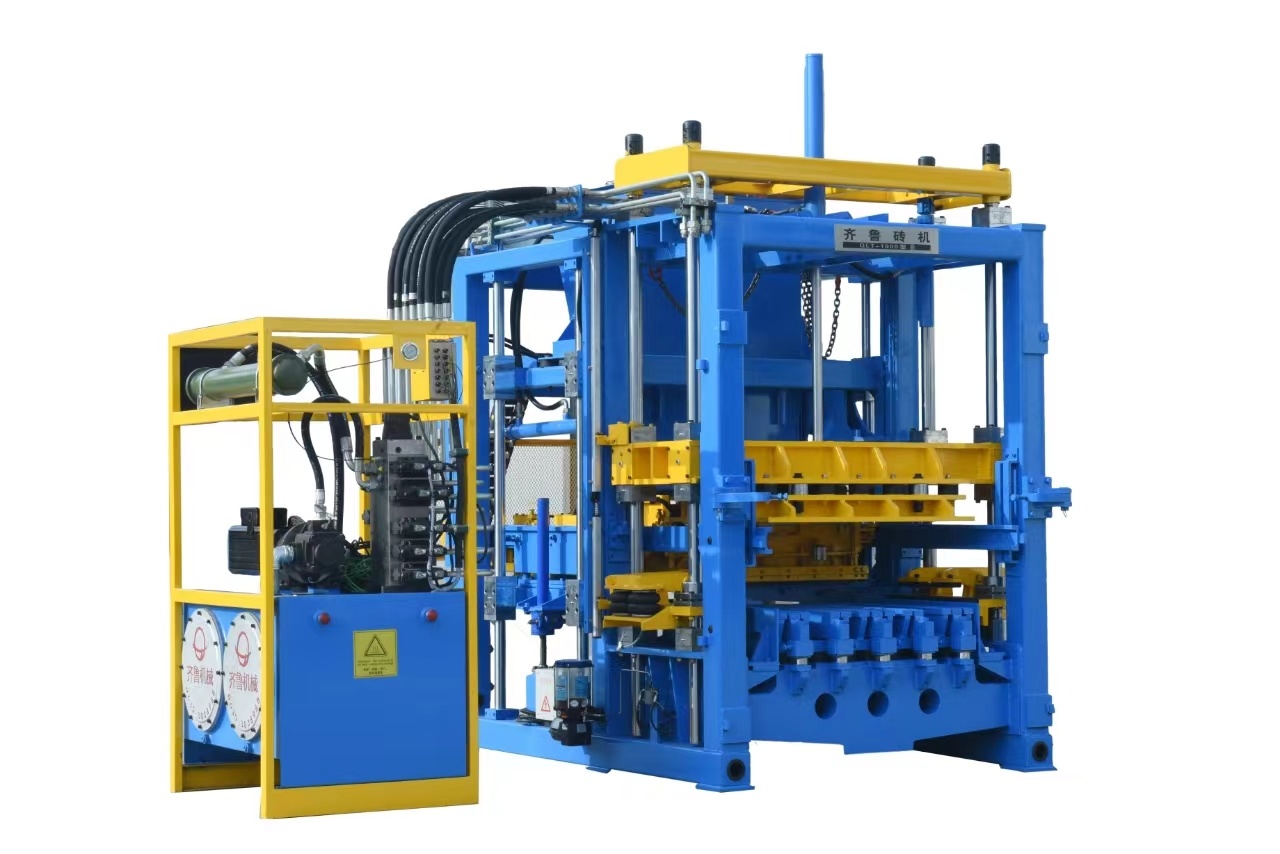

QLT1000 European version full-automatic non-burning brick machine

Classification:

Key words:

QLT1000

Product Description

European version QLT100 technical parameters

|

QLT100 type technical parameters |

|||

|

Maximum molding area |

1090 × 890mm |

vibration table |

24KW |

|

Height of finished product |

50-300mm |

vibration frequency |

47-75HZ |

|

electronic control system |

Servo |

||

|

Forming cycle |

10-20 seconds (depending on the shape of the product) |

Total installed capacity |

67.8KW |

|

Exciting force |

216KN |

Total |

13 tons |

|

Pallet Size |

1150 × 950 ×(12-35)mm |

||

|

Number of molding blocks |

390 × 190 × 190mm(12 pieces/mold) |

||

Main technical features:

1. Molding host: It adopts German advanced technology design, including 4 patented technologies (host system patent, hydraulic system patent, stacking plate system patent, vibration system patent), stable performance, airbag clamping, convenient and fast, high product density, standard size, high output, exquisite and reasonable appearance design.

2. Vibration system: 1. Adopt the patented vibration technology of Qilu brick machine, the integrated design of vibrator and vibration platform, four-dimensional servo vibration, direct-connected shaft transmission, and the vibrator adopts automatic oiling mode. 2. The Inovance servo vibration motor is directly connected to the connecting rod type soft connection transmission assembly, which saves the belt transmission link in the traditional vibration mode, and the upper and lower synchronous transmission, the vibration speed is fast, the vibration force is large, the molding speed cycle of each plate brick is increased by 3-4 seconds, and the output is increased by 20%.

3. Servo hydraulic system: The patented appearance design of Qilu brick machine is adopted, the appearance is exquisite, the trapezoidal design of the oil pipe is neatly arranged, and the direction of the oil pipe is more reasonable. The main motor adopts Huichuan servo motor, the main oil pump, double proportional valve and solenoid valve adopt German Rexroth, and the core technology of Qilu brick machine is assembled. It has stable performance, extremely low failure rate, advanced design, reasonable structure, fast and stable walking speed of each action.

4. Electric control system: Qilu brick machine computer PLC automatic control integrated technology, independent frequency conversion design for each part of the whole line. PLC and touch screen adopt Siemens, sensors, frequency converters and circuit accessories adopt famous brand accessories such as Shanghai Lanbao, Omron, Taiwan Shilin, Jie Tong, Sine, ABB, etc.

5. Distributor system: Distributor quickly transfers materials before and after shifting teeth, making the cloth more uniform, the cloth speed is fast, the product density is high, and the height is consistent. The bottom plate of the cloth car adopts Shanghai Baosteel NM400 high-strength wear-resistant plate, which greatly improves the service life. The cloth shaft adopts 35crmo quenching, which has good toughness and is not easy to break. The stirring tooth adopts 35crmo quenching, which has good toughness and wear resistance. The bolt type design makes it more convenient to replace. The cloth car runs encoder control. The storage hopper adopts electronically controlled door opening. The discharging amount can be adjusted arbitrarily according to different brick type and the blanking is more accurate.

6. Balance system: Gantry frame type and balance bar double balance are adopted, the upper and lower molds are accurately injected into the mold, the phenomenon of mold clamping is avoided, and the service life of the mold is prolonged. The upper box is designed as a double box. The middle shock-absorbing rubber pad protects the pressure head oil cylinder, and the four-point limit ensures the level of the lower pressure of the upper mold and protects the rubber pad at the same time.

7. Brick receiving machine: the operation is frequency conversion control, the speed is adjustable, and the operation is relatively stable.

8. Belt conveyor: the old traditional system is eliminated, and the latest feeder system is adopted. The finished materials are mixed twice to make the materials evenly put into the storage hopper.

9, cloth truck lifting platform: the use of lift, beautiful, practical, easy to change the mold.

10. Safety net: push-pull type is more convenient, convenient to use and safer.

Key words:

Burning-free brick machine

Previous Page

recommend products

Welcome your message consultation

TEL:+86-400-006-3568

TEL:+86-400-006-3568 E-mail:qlmszj1@163.com

E-mail:qlmszj1@163.com